EVO-LT™ System Technology

The EVO-LT™ System has been developed as a fully integrated solution and includes all required hardware for conversion to LNG operation. The EVO-LT™ System is comprised of various components and assemblies that are retrofitted into the locomotive’s engine room, engine itself, and operator cab. The installation of the EVO-LT™ System is performed onsite and without significant modification to the locomotive or engine utilizing conventional shop facilities and general technical labor. After the EVO-LT™ System has been installed, the locomotive can be operated on either 100% diesel fuel or on a combination of diesel fuel and LNG. The operating fuel mode can be manually selected if desired, however the system has been designed to automatically utilize LNG whenever it is available. In the event that the on-board LNG supply is exhausted, the System automatically reverts the engine to 100% diesel operation irrespective of operating mode or load condition. The switch from LNG/diesel (LNG+D) mode to 100% diesel mode is seamless and requires no action by the operator. After the LNG supply is replenished, the EVO-LT™ System automatically reverts the engine to LNG+D mode. When operating on LNG+D, the converted locomotive meets or exceeds OEM standards for performance, efficiency and reliability.

Engine Conversion

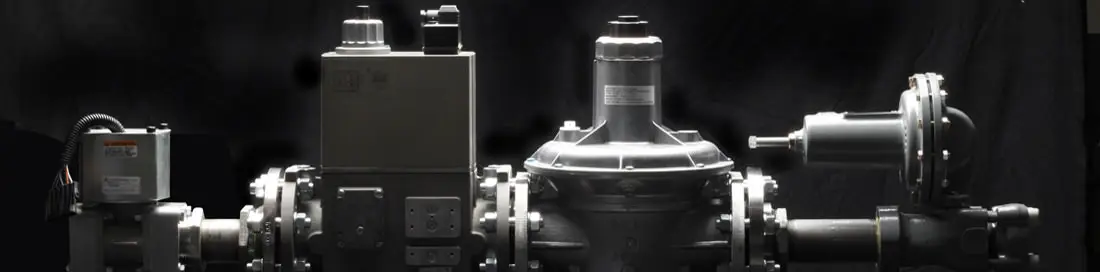

The conversion process utilizes components that are installed externally of the engine and no changes or modifications to the cylinders, pistons, fuel injectors or cylinder heads are required. The EVO-LT™ System retains the OEM diesel fuel system in its entirety and the engine maintains the capability to operate solely on diesel fuel when required. The EVO-LT™ System interfaces with the engine cooling circuit in order to supply high temperature coolant to a heat exchanger / vaporizer for efficient conversion of the LNG from a liquid to a vapor state. Once the LNG is converted to a vapor phase, it is supplied to the engine’s air-intake system at a point upstream of the turbo-compressor inlets using low restriction air-gas mixing technology. Installation of the EVO-LT™ System is performed using conventional shop tools and equipment and requires about 6 – 8 hours to complete.

Protection and Control

The EVO-LT™ System includes a powerful Electronic Control Unit (ECU) that monitors critical engine, and locomotive data and uses this information to dynamically control the operating fuel mode of the engine. The EVO-LT™ System ECU also provides sophisticated engine protection and monitoring functionality with pre-alarm, alarm and shut-down logic that allows the engine to be switched from LNG+D mode to diesel-only operation seamlessly and automatically. These protective systems and control algorithms ensure continued engine reliability and uptime when operating on LNG. The ECU monitors critical engine parameters including exhaust gas temperature, manifold air temperature, vibration, engine coolant temperature, engine speed, compressor inlet pressure and manifold air pressure. Each ECU data channel is sampled 50 times per second (50 Hz) ensuring rapid detection and correction of anomalies.

Graphical User Interface

The EVO-LT System allows for quick and simple access to both real time and logged System data using a proprietary graphical user interface (GUI) program. The GUI program is PC compatible and technical personnel can access System data using a convenient USB interface located in the operator cab. In addition to accessing System data, the GUI program is utilized during setup and commissioning of the locomotive for creation or loading of fuel mapping algorithms as well as for programming various System control, pre-alarm and alarm setpoints.